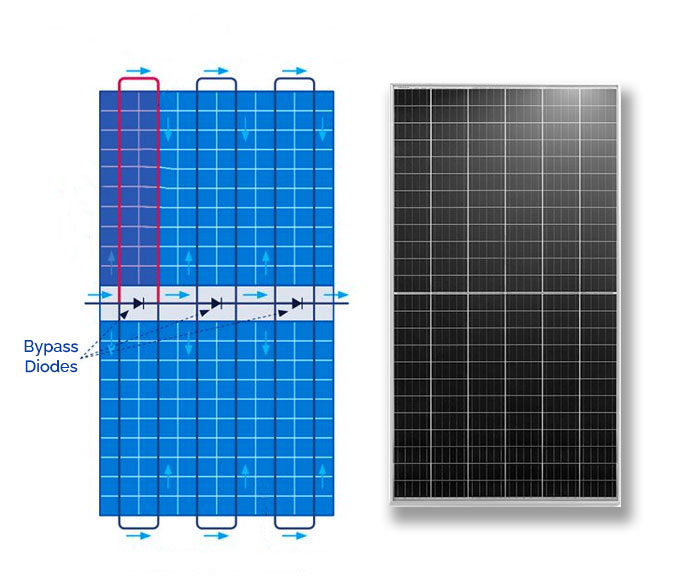

Half-cut Technology

With high precision laser cut cells, the current flowing in each bus bar is halved resulting in lower electrical resistance and an increased overall efficiency of about 2.5%.

1Remarkable performance in shaded condition

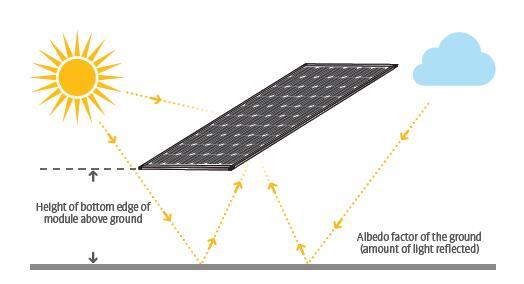

Half cell module produces energy even if part of the module is shaded. Whereas if standard full cell module is partially shaded minimum one string will completely stop producing power, this accounts to one third reduction in power generation. Moreover, it can even completely stop generating power if shaded across its breadth. Half-cut cell module is split into two parts. Each section containing half cells generates power on standalone basis but combines again before current exits the module. This structure results in power generation in non-shaded area of the module even in one of the section is partially or completely shaded, resulting in higher overall energy yield as compared to standard module. The combination of half-cut cell technology and bifacial module can amplify the gain over the effect of current-reduction.

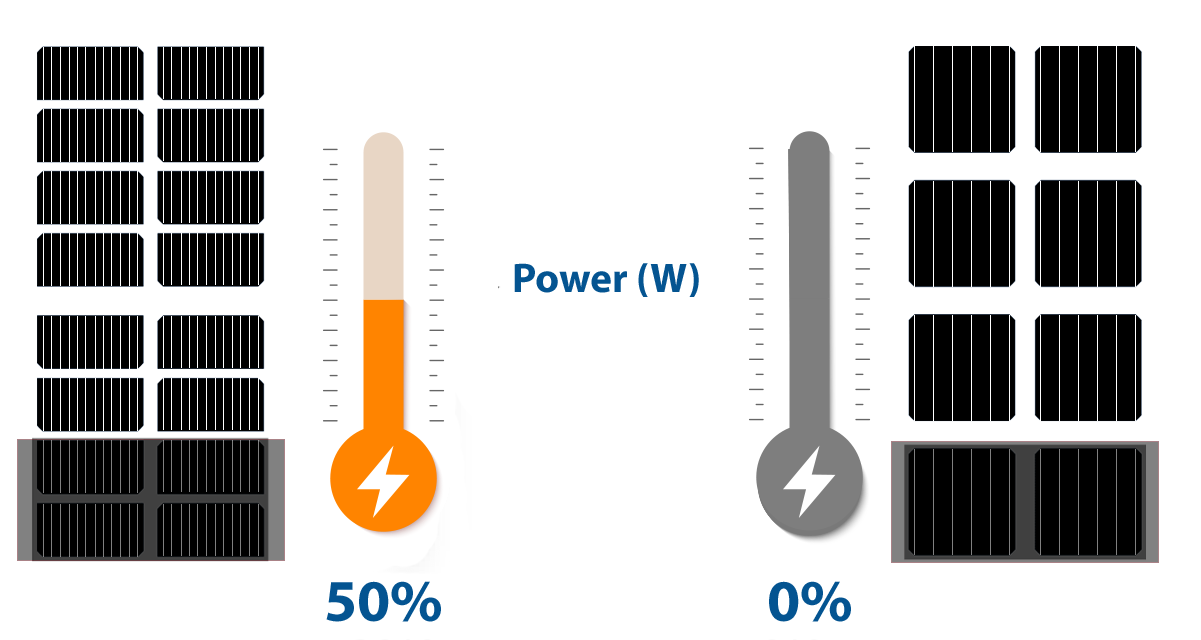

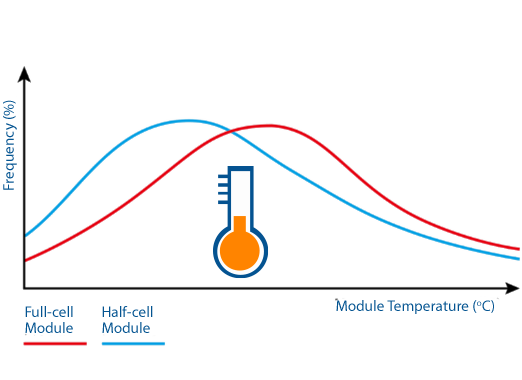

2Lower Operating Temperature

Half-cut cells have half of the working current, thereby the thermal loss is remarkably reduced. Operating temperature correspondingly decreases, and the reliability of module is improved as well as power gain.

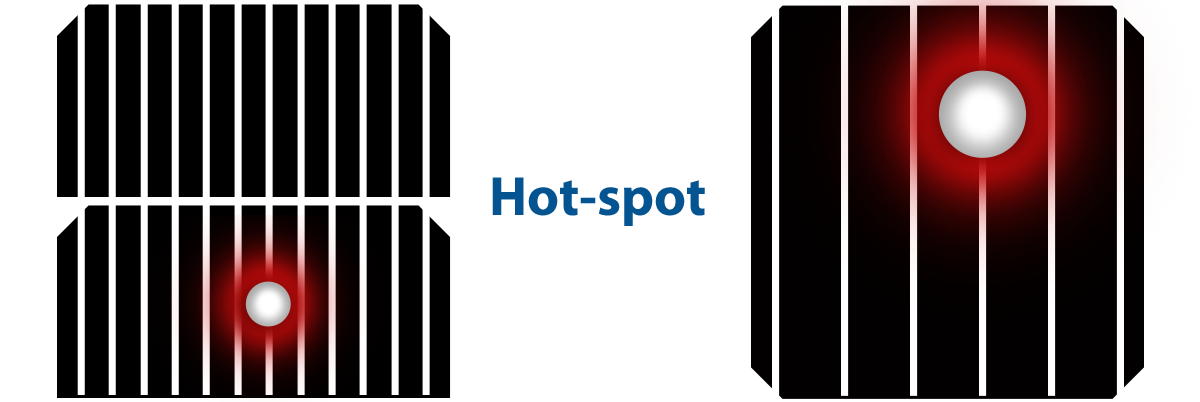

3Lower Hot Spot Temprature

Hotspots are a major source of failure for photovoltaic modules in the field. Small area shadings can drastically increase the temperature of shaded area. This phenomena is called hot spot. The prolonged hot spot could bring irreversible damage and degradation of modules. As the string current of half-cut cell modules is half of full-cell modules, the hot spot temperature decreases with reduced heat dissipation. Half-cell module design could mitigate hotspot degradation resulting in increased reliability of solar module. Result’s show the maximum hotspot cell temperature of the shaded half-cell module is 20 °C lower than that of the full-cell module .